Safety Release

Increased vigilance by HSE/OSHA inspectors in recent years has highlighted the need for improved tanker top access facilities. The majority of tanker access

is required for loading or unloading. However, in many cases, operators need to have access to tanker tops to check security of man-lids or sample product.

The most common form of tanker access and enclosure is the folding stair which can be configured with a range of steps and step widths together with safety baskets.

In case of a high variance of tankers and large working areas, a complex protecting grating system may be the better solution.

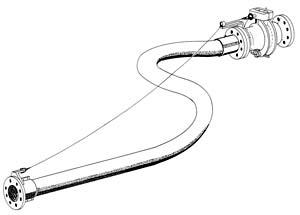

Hose Release System

Hose Release System

The Hose Release System is used for the protection of loading hoses during loading/unloading of barges, providing environmentally safe handling of loading hoses.

If the connected loading hose is stretched over the allowable working envelope, the cable will be activated. The shear pin will break and the clamp collar of

the release unit will unlock. The two halves of the coupler will divide preventing damage to the installation or the vehicle.

The spring-loaded poppets cut the product flow of the hose and the vehicle completely so that leakage is avoided.

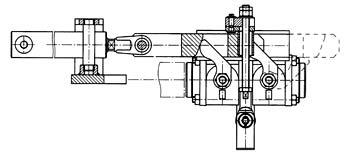

Quick Release System - Hydraulic

Quick Release System - Hydraulic

The E0790 Hydraulic Quick Release System is used for the automatic separation of a connected loading arm from a tank vehicle in the event of an accidental

drive-away whilst still connected. In this event, there is minimal loss of pressure in the rest of the connected supply.

Our loading arms and the vapour return arms are provided with a quick release system with reduced diameter. The diameter of the system is designed to be 3”

for the loading arm and 2” for the vapour return arm.

The quick release system consists of two standard ball valves and the release coupling, which is clamped together by a collar assembly. With the use of a lever,

first the ball valves are closed and then the collar release is activated. Due to the high operating force a hydraulic cylinder is required for the activation.

The system is controlled hydraulically according to the circuit diagram shown, i.e. with a hydraulic limit switch in the slew range between the F- and A-length

of the arm.

The release will be initiated either by the product arm or the vapour arm, depending on which of them is outside of its safe working envelope first.

The hydraulic accumulator and the control system are located in a control cabinet with a conductive surface.

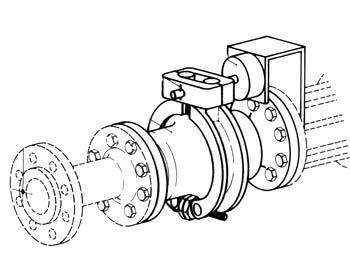

Quick Release System - Mechanical

Quick Release System - Mechanical

The Mechanical Quick Release System provides automatic disconnection of a loading arm in the event of a tanker accidentally driving away.

Simultaneously the product flow will be shut off both upstream and downstream of the disconnection point.

The system can be used on a variety of loading applications.

The quick release unit is fitted as an integral part of the outboard end (B-dimension) of the loading arm. Both valves are clamped together by a collar

assembly. The actuation cam fitted to the double swing joint activates the collar release via the Bowden cable.

Also fitted to the double swing joint is a shear pin which prevents accidental release whilst manoeuvring the loading arm.

Quick Release System - Pneumatic

Quick Release System - Pneumatic

The Pneumatic Quick Release System provides automatic disconnection of a loading arm in the event of a tanker accidentally driving away whilst

simultaneously shutting off the product flow both upstream and downstream of the disconnection point.

The system is used at single loading arm stations and bottom loading stations.

The quick release unit is fitted as an integral part of the outboard end (B-dimension) of the loading arm. Both valves are clamped together by a collar assembly

and the clamp is released by a pneumatic cylinder. A limit switch fitted to the double swing joint, and controlling the rotation angel, activates the cylinder.

The connecting flange sensor and a shear pin, also fitted to the double swing joint, prevent accidental release whilst manoeuvring the loading arm.